Working with a manufacturer who has in-house tooling offers significant benefits

Vaupell maintains in-house tooling shops in the majority of its facilities. This service provides the necessary support for our customers including top-tier OEMs in the aerospace, defense, and medical markets.

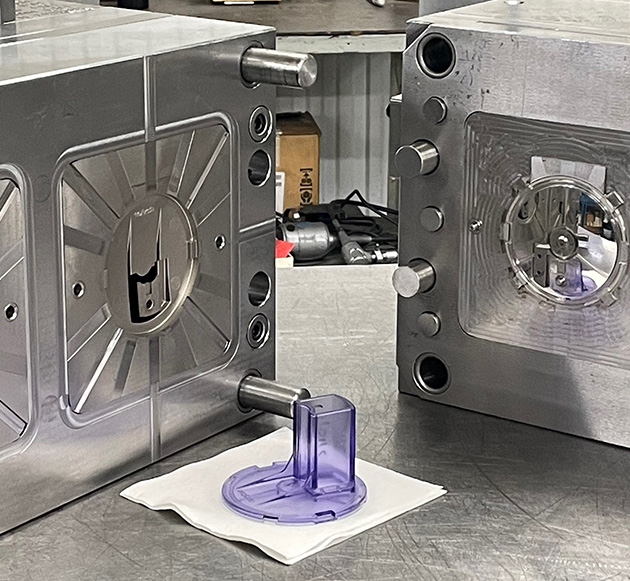

In-house tooling has proven to be an extremely economical means for our customers in expediting designs into production. By using our in-house facilities and eliminating sub-contractors, we are able to ensure the highest-grade quality throughout the entire process. Our design team has extensive experience using the state-of-the-art equipment housed in our tool room. This experience translates into immediate time and money savings for you, our customer.

Vaupell has both US-based and offshore capabilities with a tool room in Dongguan, China, providing a lower cost tooling option. Our center of excellence for injection molds is based in Constantine, MI, which supports production tool building from all production molding facilities.

Here are some advantages of collaborating with us:

Our tool shop in Constantine MI focuses on high precision machining while also providing the ability to repair and maintain production injection molds. It specializes in the design, development, and manufacturing of custom fixtures and gauges that can be used in the assembly, inspection, or test functions of our customers.

- Faster turnaround time

- Cost savings

- Quality control

- Customization and flexibility

- Streamlined communication

- Confidentiality and intellectual property protection

- Efficient problem solving

- Long-term collaboration

- Reduced lead times

- Continuous improvement

- Adaptation to market changes

Injection Molds

Our 4 global facilities maintain more than 100 injection molding presses from 17 to 1,000 tons of clamping force. This includes both vertical and horizontal presses with general molding floor capabilities and ISO Class 7 (10K) and ISO Class 8 (100K) clean room environments.