PARTS SHIPPED IN 1 TO 3 DAYS

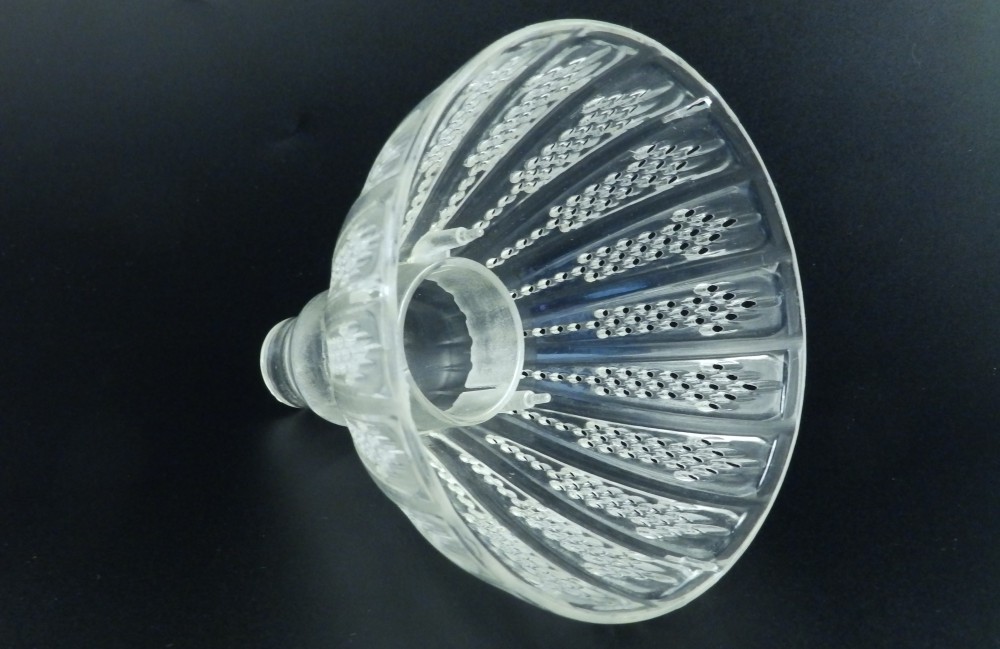

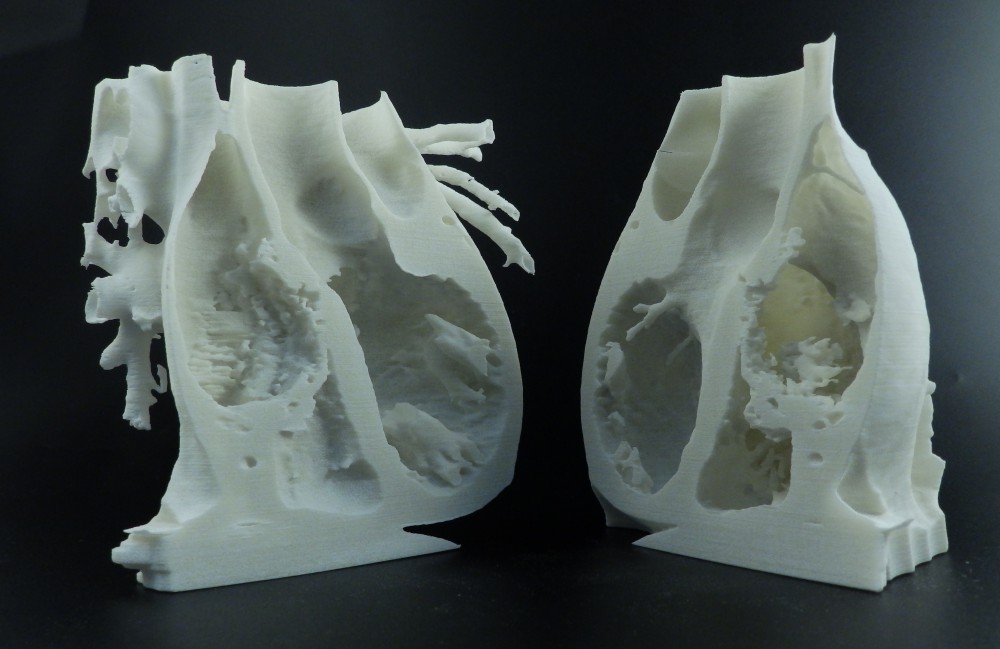

Vaupell Rapid has been making Stereolithography parts for over 20 years. It’s this experience that allows us to guide customers in the design process to create parts with short turn around and fewer iterations. Vaupell Rapid has a wide variety of resins in-stock with a broad scope of material properties to meet any industry need.

Key Features

- High accuracy and good finish

- Typical lead time 1 – 2 business days

- Can produce very complex geometries

- Variety of materials to best fit application

APPLICATION ALTERNATIVES

- Parts are fragile compared to commercially available plastics

Suggestions: FDM, Cast Urethane, SLS - Parts can be susceptible to humidity, UV exposure and high temperatures

Suggestions: SLS, FDM